联系我们 Contact

产品配置

Main parts

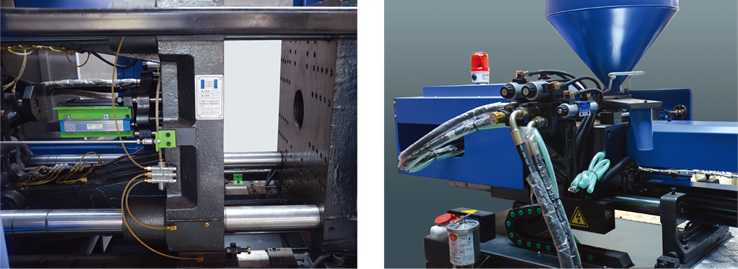

注射部件

INJECTION UNIT

双导柱支承、双缸平衡注射,无级高扭矩液压马达直接驱动螺杆熔胶装置,力封闭型座进装置,优质氮化合金钢螺杆及料筒,表面双金属处理延长寿命,可供A、B、C三种直径的螺杆,配合多种专用注射装置,确保各种塑料的注射成型。

Double guide post support, twin-cylinder balaced injection, continuous high torsion hydraulic motor directly drives the screw plastic melting device, forcefully closed type base advance device, high quality nitroalloy steel screw and feed cylinder. Bi-metal surface treatment makes extra long service life possible. Screws of three different diameters A,B and C are available. When combing various special-purposed injection devices, it can ensure the forming of all kinds of plastic.

Double guide post support, twin-cylinder balaced injection, continuous high torsion hydraulic motor directly drives the screw plastic melting device, forcefully closed type base advance device, high quality nitroalloy steel screw and feed cylinder. Bi-metal surface treatment makes extra long service life possible. Screws of three different diameters A,B and C are available. When combing various special-purposed injection devices, it can ensure the forming of all kinds of plastic.

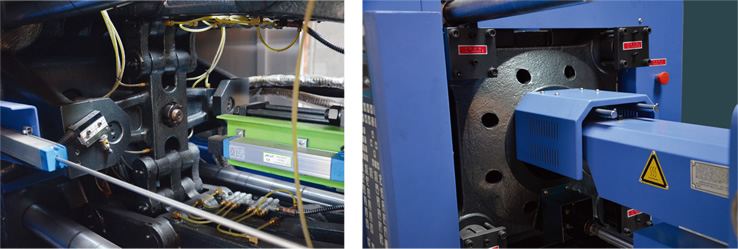

电器部件

ELECTRIC UNIT

采用进口塑机专用电脑,CPU分工控制处理多组模具成型资料储存功能,多点PID料温控制、注射、预塑、开合模动作采用高精度电子尺控制,提高控制系统响应速度及稳定性。

With adoption of imported computer special for injection molding machines, CPU controlled divided process, multi-group mold forming data storage function, muti-point PID material temperature control, injection, pre-molding and mold clamping and unclamping actions are controlled by high-precision electronic ruler to improve the response speed and stability of the control system.

With adoption of imported computer special for injection molding machines, CPU controlled divided process, multi-group mold forming data storage function, muti-point PID material temperature control, injection, pre-molding and mold clamping and unclamping actions are controlled by high-precision electronic ruler to improve the response speed and stability of the control system.

合模部件

MOULD CLAMPING UNIT

斜排列五支点肘式机构,计算机参数优化设计,模板经过有限元分析设计,采用箱式支架模板连体结构,采用机械可调节式活动模板支承,确保合模部件的刚性及使用寿命。

Slant arrangement of five-pivot toggie typed mechanism, computer parameter optimized disign. Based on the finite element analytic design. The mold plate adopts box typed, and integrated structure of support frame and mold plate. Machine of smome types are clip plate integrated and adopt mechanially adjustable and moveable plate support to ensure the rigidity and service life of the mold-clamping unit.

Slant arrangement of five-pivot toggie typed mechanism, computer parameter optimized disign. Based on the finite element analytic design. The mold plate adopts box typed, and integrated structure of support frame and mold plate. Machine of smome types are clip plate integrated and adopt mechanially adjustable and moveable plate support to ensure the rigidity and service life of the mold-clamping unit.

液压部件

HYDRAULIC UNIT

采用进口名牌液压元件,差动高速合模装置,注射多级控制,系统采用压力流量比例控制,预留标准抽芯装置,大型机配备逻辑插装阀系统,确保机器动作达到最佳状态。

With adoption of imported famous brand hydraulic components, differential high-speed mold clamping device, multi-level injection control and the system has employed pressure=flow ratio control with reservation of standard core puller. Large machines are fitted with logic cartridge valve systm, which has secured the optimized status of machine actions.

With adoption of imported famous brand hydraulic components, differential high-speed mold clamping device, multi-level injection control and the system has employed pressure=flow ratio control with reservation of standard core puller. Large machines are fitted with logic cartridge valve systm, which has secured the optimized status of machine actions.