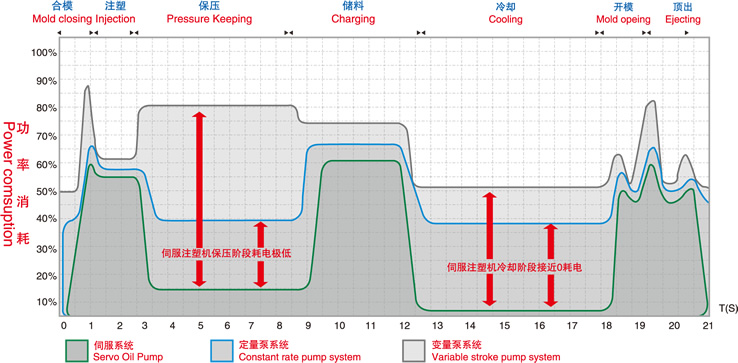

| 伺服节能注塑机数字时代已来临 | 近年来,随着技术的进步用户对注塑机的效率、稳定性、可维护性、噪音等方面都提供了越来越高的要求。注塑机的驱动部分从变频器的应用,变量泵技术逐渐演变成伺服技术。伺服节能注塑机驱动系统在兼顾成本与性能稳定性的前提下,完美的解决了用户最为关心的效率问题,以及工艺重复性、噪音等方面的要求,代表了国内先进注塑机的发展方向。与主流的定量泵与变量泵系统相比,伺服节能注塑机结合了伺服电机快递的无极调速特性和液压油泵的自主调节油压特性,带来了巨大的节能潜力。 In recent years,customer has got more concerned about such key features of machine as efficency, stabIlity, maintainabllity, moise, etc. With technology developing. Drive part of injection molding maching has good cost-pertormance ratio and can meet customer is high requirement as well as removing their above concerns about injection molding maching completey. Serve nergy-saving injection molding machine,compared with most machines conflgures with either ration pump or variable displacement pump drive system, achieves significant advantage in energy saving byintegrating both key technical features:stepless speed adjustment of serve motor and all pressure independent adjustment of hydraulic pump respectively.

随着总线通讯技术的发展,充分拓展了伺服节能注塑机电气部分一体化整合的前景,通过注塑机电脑与伺服驱动器间的数据高速传输,实现了驱动与控制之间的无缝连接。完美的解决了常规伺服节能注塑机电气调试复杂以及整体系统不稳定等问题。 Fast developing canbus technology helps to realize seamless link between drive and control through high-speed data transmission between injection machine computer and serve driver,further hearld full integration of ekectrical system of injection machine and solve out such problems as complicated electrical adjustment and unstability of the whole system. |